WE BELIEVE THAT EACH CREATION IS A MASTERPIECE...

With that, we transform precious metals and gemstones into wearable works of art. Each piece of jewelry is inspired from the nature that surrounds us. We invite you to join us and explore the unique creation journey we take in bringing a piece of jewelry, our art, to life. Here is a behind-the-scenes exploration of our jewelry design process combining traditional techniques like drawing, wax carving, soldering, hand fabricating, casting, and gem setting along with modern techniques like CAD, modeling, and laser welding.

OUR PROCESS

Step 1

Our creative process starts with “Inspiration, Exploration, and Gem Selection”. Whether the inspiration originates with you or from within our own studio, we explore the idea together visually with gems.

Step 2

Next, we put the ideas on paper – drawing each design to perfect the vision. Our sketchbook is like a flowing journal of ideas, concepts, and designs we can always explore further or choose to bring to life.

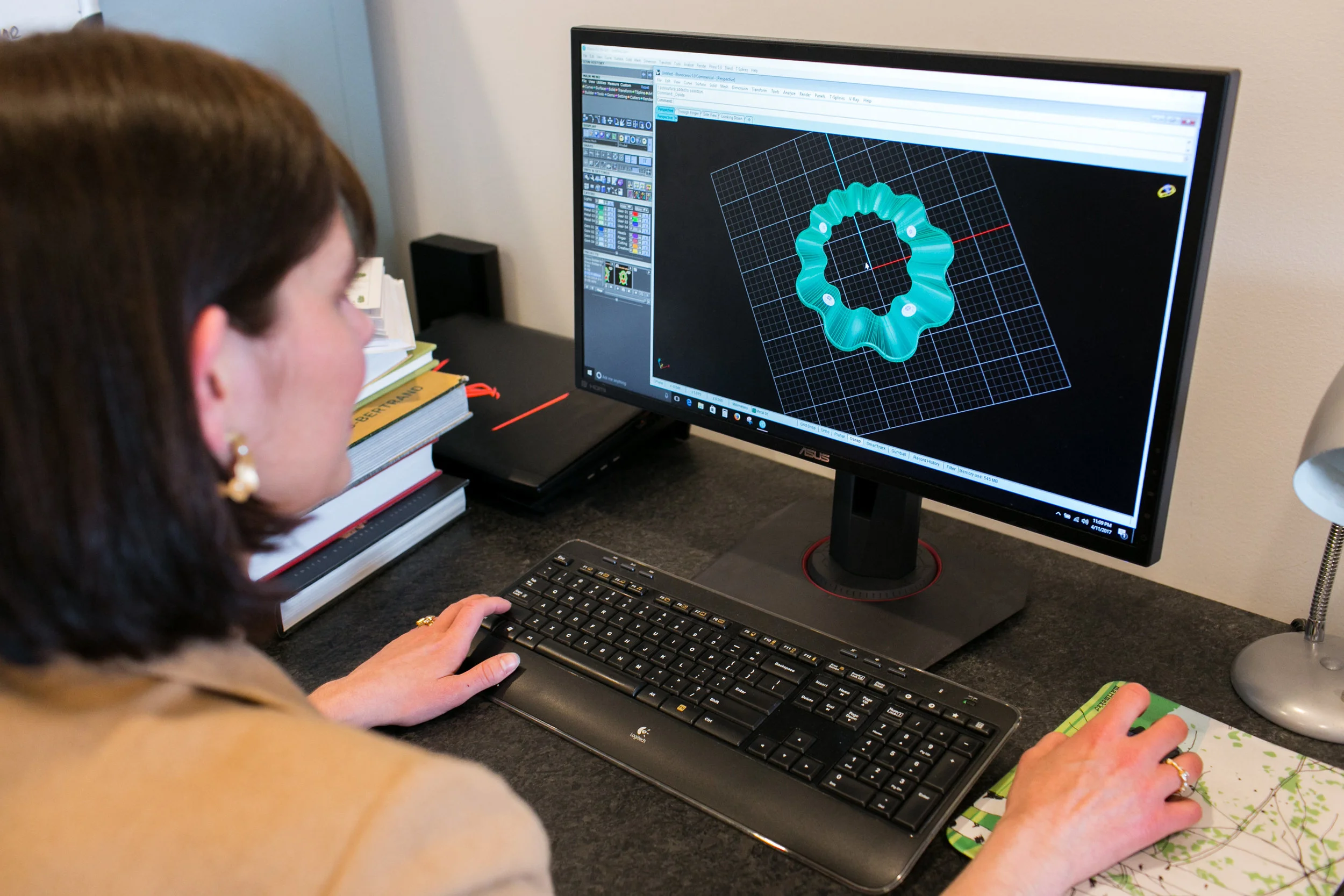

Step 3

From our sketch book, we take the designs to the next level by using CAD to perfect the original vision.

Step 4

Next, we create a wax model from the CAD image.

Step 5

The wax model is sprued to a base and a steel flask is fit over it. The steel flask is filled with liquid investment (similar to plaster of paris). After the investment hardens, the rubber base is removed and the flask is put into a kiln to burn out the wax creating a void that will be filled with molten gold.

Step 6

The flask is taken out of the kiln at 1000 degrees Fahrenheit and the gold is melted in a crucible with a torch and poured into the flask which is under vacuum pressure.

Step 7

The hot steel flask is quenched in water which unveils the gold casting from the investment – always a magical moment!

Step 8

A hand saw is used to separate the gold castings from the casting tree and button.

STEP 9

Time for benchwork; from filing and sanding to soldering and hammering all the little steps that mean so much in creating a special piece of jewelry.

Step 10

Gems all fit by hand under a microscope using a rotary burr. Cutting gold away bit by bit until the gem fits snugly and is ready to be set.

Step 11

Diamonds are mapped out and set one by one under a microscope.

Step 12

Polishing and finishing details give each jewelry creation life and a unique character.

Step 13

Finally, each of our jewelry pieces is hand-signed. Also inscribed on each piece is a unique number, which is recorded in our archives.

Step 14

An idea, a design, a creation entirely brought to life in our studio. But the story never ends, who will wear this, where will it end up, where will it travel, what will it commemorate, will she say yes, will he say yes, will this be a family heirloom, who will smile and recall a special memory when they see it – now the story begins, with you.